Jay Jagdamba Quality Policy – ISO Certified Stainless Steel Manufacturer

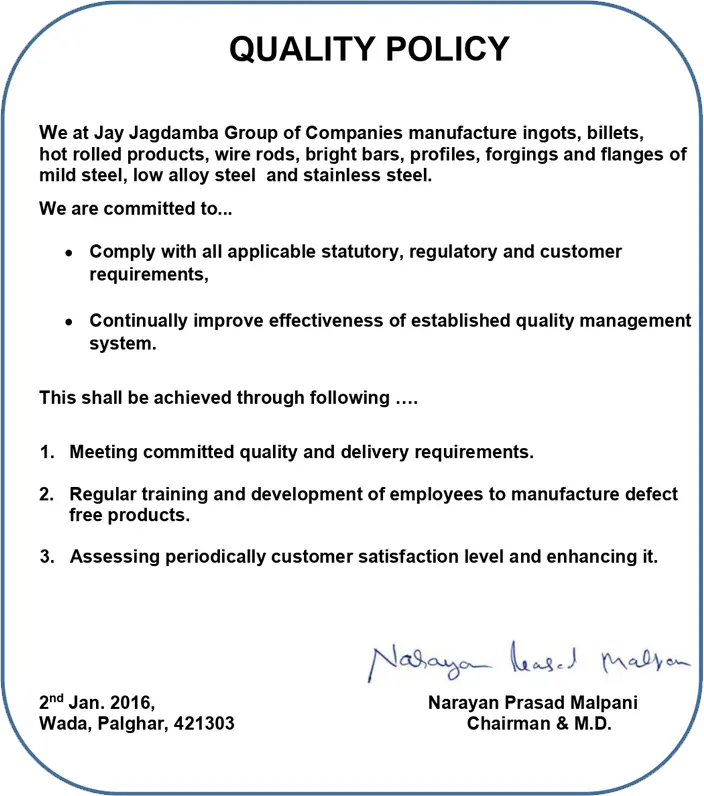

We believe that quality is the core principle guiding our manufacturing operations. Our quality team aims to ensure that the finest of our products reach our customers and consistently meets international standards.

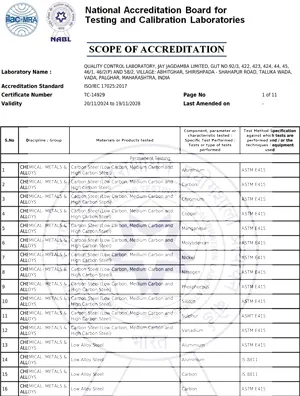

We conduct several quality checks at each of our divisions including, inter alia, scrap analysis and verification, chemical composition tests, mechanical properties test, micro-structural tests, corrosion resistance test, and dimensional and surface finish test.

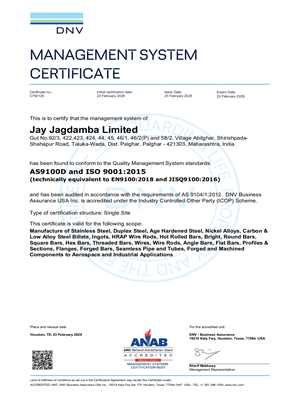

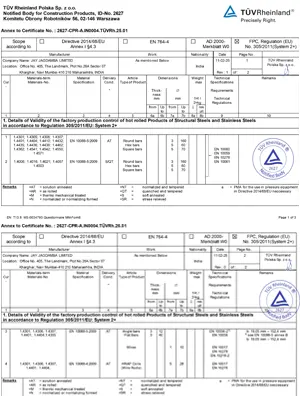

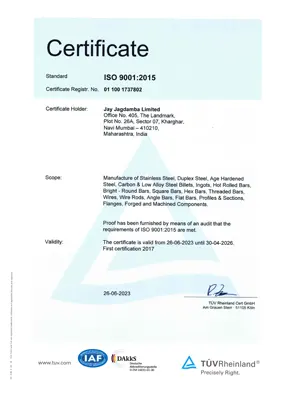

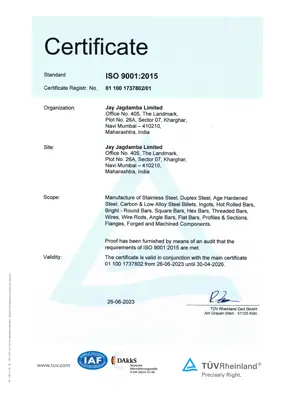

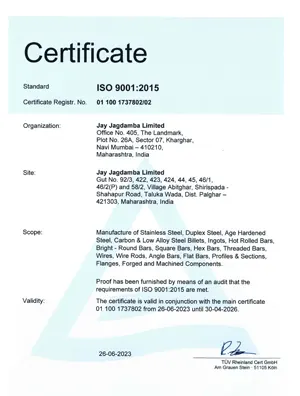

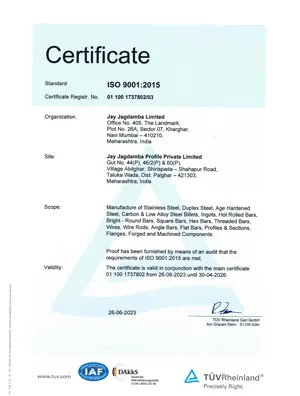

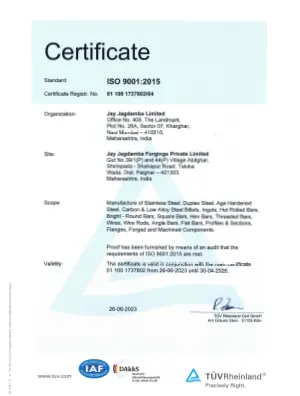

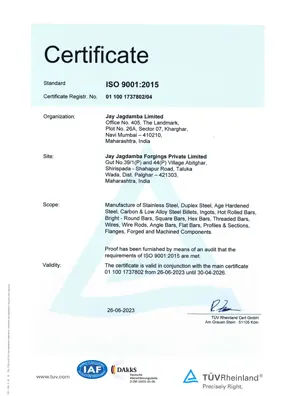

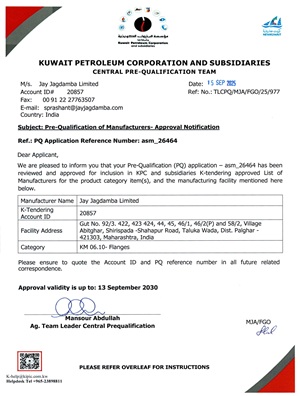

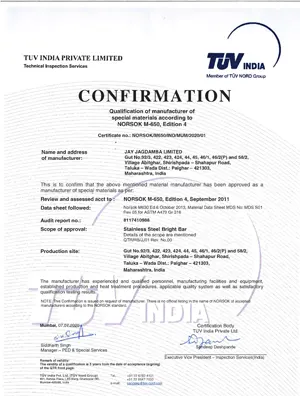

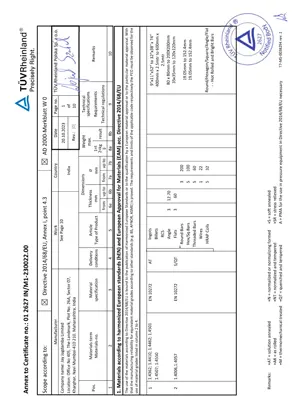

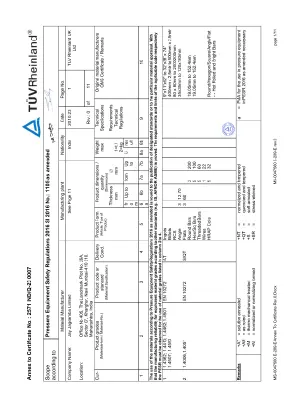

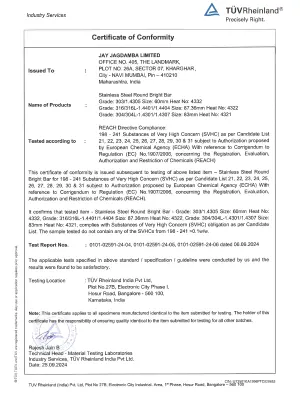

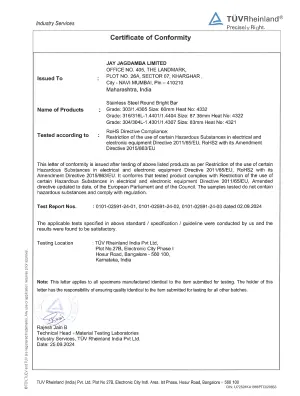

Our Manufacturing Facilities have been certified in accordance with international standards of quality management systems such as ISO: 9001:2015, environmental management systems, ISO:14001:2015, EN 764-5:2014 issued by TÜV Rheinland UK.

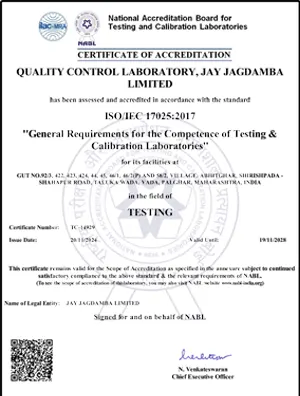

Our operations are supported by a well-accredited laboratory certified by the National Accreditation Board for Testing and Calibration Laboratories in the field of testing, enabling seamless production, stringent quality control, and efficient delivery of diverse, high-quality products. Our commitment to quality is reflected in our rigorous quality control processes.

PMI (Positive Material Identification) testing.

Optical emission spectroscopy (OES) analysis.

Radioactive contamination Test.

Visual Inspection.

Surface Finish Inspection.

Dimensional Inspection.

Macrostructural Analysis.

Visual Inspection.

Surface Finish Inspection.

Dimensional Inspection.

Step-Down Test.

Tensile Test.

Determination of non-metallic inclusion content.

Measurement of Decarburized depth of Steel.

Jominy End quench test.

Magnetic Particle Testing.

Ultrasonic Testing.

Pyrometer testing.

Hardness Test.

PMI (Positive Material Identification) testing.

Estimating Average grain Size Number (G).

Visual Inspection.

Tensile Test.

Hardness Test.

Impact Test.

Corrosion Test.

Dimensional Inspection.

Surface Finish Inspection.

Estimating Average grain Size Number (G).

Straightness Test.

Magnetic Particle Testing.

Ultrasonic Testing.

Eddy Current Testing (ET).

PMI (Positive Material Identification) testing.

Determination of non-metallic inclusion content.

Dimensional Controls with CMM Machine.

Visual Inspection.

Surface Finish Inspection.

Tensile Test.

Hardness Test.

Impact Test.

Corrosion Test.

Grain Flow Test.

Dye Penetrant Test.

Ultrasonic Testing.

AS9100

AS9100