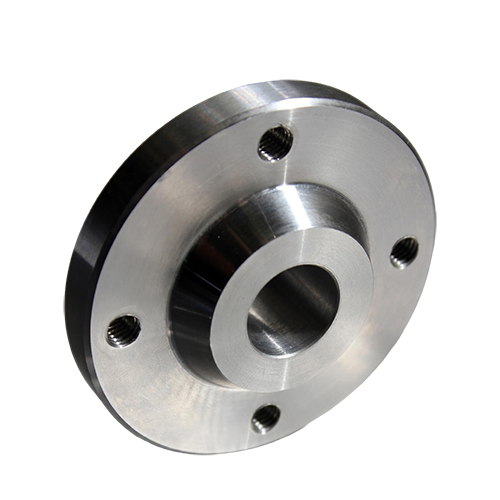

Stainless Steel Flanges

SS Flanges Manufacturer, Stainless Steel Flanges Manufacturers India - JAY JAGDAMBA LIMITED

Stainless steel flanges are critical components used in piping systems to connect pipes, valves, pumps, and other equipment. These flanges provide a secure, leak-proof connection, ensuring structural integrity and ease of maintenance. Made from high-quality stainless steel, they offer excellent resistance to corrosion, rust, and extreme temperatures, making them ideal for industries that require high durability and reliability

SIZE RANGE OF FLANGES MANUFACTURED

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| ASME B16.5 | Blind | 150 LBS | 1/2" to 24" |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 16" | ||

| 2500 LBS | 1/2" to 12" | ||

| Weld Neck | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 16" | ||

| 2500 LBS | 1/2" to 12" | ||

| Slip-on | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 2.1/2" | ||

| Socket Weld | 150 LBS | 1/2" to 3" | |

| 300 LBS | 1/2" to 3" | ||

| 600 LBS | 1/2" to 3" | ||

| 1500 LBS | 1/2" to 2.1/2" | ||

| Lap Joint | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 16" | ||

| 2500 LBS | 1/2" to 12" | ||

| Threaded | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 2.1/2" | ||

| 2500 LBS | 1/2" to 2.1/2" |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| ASME B16.47 | Series A Blind, Weld Neck | 150 LBS | 26" to 48" |

| 300 LBS | 26" to 48" | ||

| 400 LBS | 26" to 30" | ||

| 600 LBS | 26" to 30" | ||

| Series B Blind,Weld Neck | 75 LBS | 26" to 54" | |

| 150 LBS | 26" to 52" | ||

| 300 LBS | 26" to 48" | ||

| 400 LBS | 26" to 46" | ||

| 600 LBS | 26" to 30" |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Size Range |

|---|---|---|

| ASME B16.9 | Short Pattern Stub Ends (Type A, Type B and Type C) | 1/2" to 24" |

| Long Pattern Stub Ends (Type A, Type B and Type C) | 1/2" to 12" |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| DIN Flanges | DIN2527 | PN6 | DN10 to DN500 |

| PN10 | |||

| PN16 | |||

| PN25 | |||

| PN40 | |||

| PN64 | DN10 to DN400 | ||

| PN100 | DN10 to DN350 | ||

| DIN2566 | PN10 | DN10 to DN100 | |

| PN16 | |||

| DIN2573 | PN6 | DN10 to DN500 | |

| DIN2576 | PN10 | DN10 to DN500 | |

| DIN2631 | PN6 | DN10 to DN1200 | |

| DIN2632 | PN10 | DN10 to DN1200 | |

| DIN2633 | PN16 | DN10 to DN1200 | |

| DIN2634 | PN25 | DN10 to DN1000 | |

| DIN2635 | PN40 | DN10 to DN500 | |

| DIN2636 | PN64 | DN10 to DN400 | |

| DIN2637 | PN100 | DN10 to DN350 | |

| DIN2638 | PN160 | DN10 to DN300 | |

| DIN2641 | PN6 | DN10 to DN1200 | |

| DIN2642 | PN10 | DN10 to DN800 | |

| DIN2655 | PN25 | DN10 to DN500 | |

| DIN2656 | PN40 | DN10 to DN400 | |

| DIN2673 | PN10 | DN10 to DN1000 |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| EN 1092-1 | Type 01 (Plate Flange) Type 02 & Type 04(Loose Plate Flange) | PN2.5 | DN10 to DN1200 |

| PN6 | DN10 to DN1200 | ||

| PN10 | DN10 to DN1200 | ||

| PN16 | DN10 to DN1200 | ||

| PN25 | DN10 to DN1000 | ||

| PN40 | DN10 to DN600 | ||

| PN63 | DN10 to DN400 | ||

| PN100 | DN10 to DN350 | ||

| Type 05 (Blind Flange) | PN2.5 | DN10 to DN1200 | |

| PN6 | DN10 to DN1200 | ||

| PN10 | DN10 to DN1200 | ||

| PN16 | DN10 to DN1200 | ||

| PN25 | DN10 to DN1000 | ||

| PN40 | DN10 to DN600 | ||

| PN63 | DN10 to DN400 | ||

| PN100 | DN10 to DN350 | ||

| PN160 | DN10 to DN300 | ||

| PN250 | DN10 to DN250 | ||

| PN320 | DN10 to DN250 | ||

| PN400 | DN10 to DN200 | ||

| Type 11 (Welding Neck Flange) | PN2.5 | DN10 to DN1200 | |

| PN6 | DN10 to DN1200 | ||

| PN10 | DN10 to DN1200 | ||

| PN16 | DN10 to DN1200 | ||

| PN25 | DN10 to DN600 | ||

| PN40 | DN10 to DN400 | ||

| PN63 | DN10 to DN350 | ||

| PN100 | DN10 to DN350 | ||

| PN160 | DN10 to DN300 | ||

| PN250 | DN10 to DN250 | ||

| PN320 | DN10 to DN250 | ||

| PN400 | DN10 to DN200 | ||

| Type 12 (Hubbed Slip On Flange) | PN6 | DN10 to DN300 | |

| PN10 | DN10 to DN600 | ||

| PN16 | DN10 to DN1000 | ||

| PN25 | DN10 to DN600 | ||

| PN40 | DN10 to DN600 | ||

| PN63 | DN10 to DN150 | ||

| PN100 | DN10 to DN150 | ||

| Type 13 (Hubbed Threaded Flange) | PN6 | DN10 to DN300 | |

| PN10 | DN10 to DN600 | ||

| PN16 | DN10 to DN600 | ||

| PN25 | DN10 to DN600 | ||

| PN40 | DN10 to DN600 | ||

| PN63 | DN10 to DN150 | ||

| PN100 | DN10 to DN150 | ||

| Type 32 (Weld on collar Plate) | PN6 | DN10 to DN600 | |

| PN10 | DN10 to DN600 | ||

| PN16 | DN10 to DN600 | ||

| PN25 | DN10 to DN600 | ||

| PN40 | DN10 to DN600 | ||

| Type 34 (Weld Neck Collar) | PN10 | DN10 to DN600 | |

| PN16 | DN10 to DN600 | ||

| PN25 | DN10 to DN600 | ||

| PN40 | DN10 to DN600 | ||

| Type 35 (Weldring Neck) | PN10 | DN10 to DN1000 | |

| PN16 | DN10 to DN1000 | ||

| PN25 | DN10 to DN800 | ||

| PN40 | DN10 to DN400 |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| EN 1759-1 | Type 05 Blank Flange | 150 LBS | 1/2" to 24" |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 16" | ||

| 2500 LBS | 1/2" to 12" | ||

| Type 11 Weld Neck Flange | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 16" | ||

| 2500 LBS | 1/2" to 12" | ||

| Type 12 Hubbed Slip-on Flange for Welding | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 2.1/2" | ||

| Type 14 Hubbed Socket Weld Flange | 150 LBS | 1/2" to 3" | |

| 300 LBS | 1/2" to 3" | ||

| 600 LBS | 1/2" to 3" | ||

| 1500 LBS | 1/2" to 2.1/2" | ||

| Type 15 Loose Hubbed Flange for lapped Pipe End | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 16" | ||

| 2500 LBS | 1/2" to 12" | ||

| Type 13 Hubbed Threaded Flange | 150 LBS | 1/2" to 24" | |

| 300 LBS | 1/2" to 24" | ||

| 400 LBS | 1/2" to 24" | ||

| 600 LBS | 1/2" to 24" | ||

| 900 LBS | 1/2" to 20" | ||

| 1500 LBS | 1/2" to 2.1/2" | ||

| 2500 LBS | 1/2" to 2.1/2" |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| JIS B2220 | Slip-On Plate Flange (SOP), Slip-On Hub (SOH),Socket Welding flnge (SW), Welding neck flange (WN), Lapjoint (LJ), Threaded flange(TR) Blank flange (BL) |

5K | DN10 to DN600 |

| 10K | |||

| 15K | |||

| 20K | |||

| 30K |

The complete size range are given below:

| Specification (Latest Edition) | Flanges Type | Pressure Class | Size Range |

|---|---|---|---|

| AWWA C207 | Ring Flanges | Class B (86 psi) | 4" to 42" |

| Class D (175- 150 psi) | 4" to 42" | ||

| Class E 275 psi | 4" to 42" | ||

| Class F (300 psi) | 4" to 36" | ||

| Hub Flanges | Class D (175- 150 psi) | 4" to 42" | |

| Class E 275 psi | 4" to 42" | ||

| Blind Flanges | Class B (86 psi) | 4" to 42" | |

| Class D (175- 150 psi) | 4" to 42" | ||

| Class E 275 psi | 4" to 32" | ||

| Class F (300 psi) | 4" to 26" | ||

| AWWA C228 | Ring Flanges | SA (50 psi) | 2" to 42" |

| SB (86 psi) | 2" to 42" | ||

| SD (175- 150 psi) | 2" to 42" | ||

| SE (275 psi) | 2" to 42" | ||

| SF (300 psi) | 4" to 36" | ||

| Blind Flanges | SA (50 psi) | 2" to 42" | |

| SB (86 psi) | 2" to 42" | ||

| SD (175- 150 psi) | 2" to 42" | ||

| SE (275 psi) | 2" to 32" | ||

| SF (300 psi) | 4" to 26" |

ASTM 182/182M: F304, F304L, F304H, F316, F316L, F316H, F347, F347H, F317, F317L, F321

ASME SA182/182M: F321H, F316Ti, F347 , F347H, F51, F60 & F53

ASTM A403/403M

DIN 10222-5: 1.4301, 1.4306, 1.4307, 1.4541, 1.4571, 1.4401, 1.4404, 1.4410, 1.4438, 1.4450, 1.4462

S5S, S10, S10S, S20, S30, S40, S40S, S60, S80, S80S, S100, S120, S140, S160, STD, XS, XXS

Flat face, Raised face, Large Raised face, Ring joint, Tongue & Groove face (large & small), Male-Female face

Stock Finish serration, Spiral or Phonographic Serration, Concentric Serration, Smooth Finish

- Tensile testing machine

- Impact testing machine

- Hardness testing machine

- Microscope

- Mobile spectrometer for PMI test : X-ray fluorescence test-gun & OES-Optical Emission Spectrometry

- Surface roughness tester

- IGC test facilities

- Dye penetrate test

- Ultrasonic testing machine

END USE:

In the oil & gas and petrochemical industries, they are essential for high-pressure and high-temperature pipeline systems transporting crude oil, natural gas, and refined products. The power generation sector, including thermal, nuclear, and renewable energy plants, relies on flanges for steam, water, and fuel distribution systems. Water treatment and wastewater management facilities use stainless steel flanges for their durability and resistance to harsh chemicals. In the food & beverage and pharmaceutical industries, hygienic-grade flanges ensure contamination-free processing. The marine and shipbuilding sector depends on stainless steel flanges for seawater piping systems due to their excellent resistance to saltwater corrosion. Additionally, HVAC, construction, and chemical processing industries use these flanges for structural stability, fluid control, and long-lasting performance in demanding environments.