Our Manufacturing Facilities are equipped with a comprehensive range of capabilities, including a steel melting shop featuring induction furnaces, argon oxygen decarburization (“AOD”), pit-side casting for producing custom-dimension ingots, and continuous casting (“Concast”) processes for manufacturing billets through computerized operating systems. Our rolling mills incorporate multiple sizing facilities, allowing us to produce angles, flats, and a wide range of rolled bars in various shapes and dimensions using custom dies developed in-house. In addition to rolling operations, our Manufacturing Facilities also includes advanced processing for bright bars, including annealing heat treatment, automatic peeling, pickling, centerless surface grinding, and thread machining. We also manufacture bright wires using combined annealing, drawing and pickling, utilizing outsourced wire rods as inputs.

Our specialized flange production unit leverages CNC (Computer Numerical Control) and VMC (Vertical Machining Centre) machinery to ensure precision and consistency. These operations are supported by a well-accredited laboratory certified by the National Accreditation Board for Testing and Calibration Laboratories (NABL) in the field of testing. This in-house laboratory, coupled with continuous objective monitoring, allows for seamless production, stringent quality control, and efficient delivery of high-quality products.

- Induction Furnaces.

- Argon Oxygen Decarburization (“AOD”).

- Pit-side casting for producing custom-dimension Ingots.

- Continuous Casting Machine

- 16"

- 12"

- Wire Rod Coil Solution Annealing.

- Round Bar Annealing.

- Solution Annealing.

- Quench & Tempering.

- Straightening Machines.

- Peeling Line With Belt Polishing.

- Centreless Grinding Machines.

- Combined Drawing Machine.

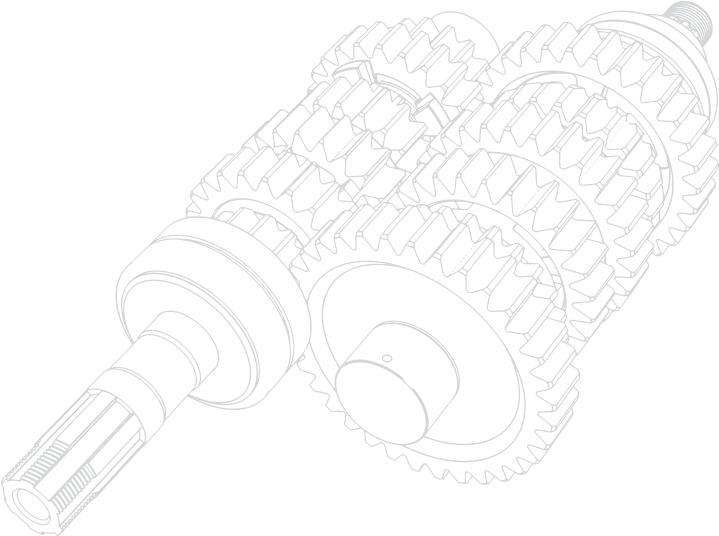

- CNC (Computer Numerical Control)

- VMC (Vertical Machining Centre)